Failure mode and effects analysis (FMEA; often written with "failure modes" in plural) is the process of reviewing as many components, assemblies, and...

46 KB (5,576 words) - 22:57, 29 May 2025

Failure mode effects and criticality analysis (FMECA) is an extension of failure mode and effects analysis (FMEA). FMEA is a bottom-up, inductive analytical...

23 KB (2,383 words) - 13:42, 4 December 2024

to prevent product failures occurring in the first place, including failure mode and effects analysis (FMEA) and fault tree analysis (FTA), methods which...

15 KB (1,765 words) - 03:35, 31 July 2024

Failure modes, effects, and diagnostic analysis (FMEDA) is a systematic analysis technique to obtain subsystem / device level failure rates, failure modes...

12 KB (1,433 words) - 13:35, 3 January 2025

cracking. Failure analysis Failure mode and effects analysis (FMEA) Failure modes, effects, and diagnostic analysis (FMEDA) Failure rate Forensic electrical...

5 KB (663 words) - 05:50, 2 June 2025

techniques: Five whys, Failure mode and effects analysis (FMEA), Fault tree analysis, Ishikawa diagrams, and Pareto analysis. There are essentially two...

30 KB (3,904 words) - 01:52, 30 May 2025

software. Failure modes with identical effects can be combined and summarized in a Failure Mode Effects Summary. When combined with criticality analysis, FMEA...

25 KB (3,022 words) - 14:38, 15 June 2025

Ishikawa diagram (redirect from Cause-and-effect analysis)

Weeden, Marcia M. (1952). Failure mode and effects analysis (FMEAs) for small business owners and non-engineers : determining and preventing what can go...

10 KB (1,201 words) - 13:14, 28 April 2025

concurrency, they are executable, and they can be simulated, model checked, and used to undertake failure mode and effects analysis. They can be used equally...

47 KB (5,252 words) - 06:36, 21 June 2025

reliability analysis until after the Challenger accident in 1986. Instead, NASA decided to rely on the use of failure modes and effects analysis (FMEA) and other...

33 KB (4,012 words) - 02:43, 9 March 2025

Design review based on failure mode (DRBFM) is a tool originally developed by the Toyota Motor Corporation. This tool was developed based on the philosophy...

6 KB (794 words) - 03:52, 11 October 2024

ARP4761 (category Handbooks and manuals)

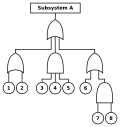

(SSA) Fault Tree Analysis (FTA) Failure Mode and Effects Analysis (FMEA) Failure Modes and Effects Summary (FMES) Common Cause Analysis (CCA), consisting...

8 KB (1,020 words) - 14:25, 10 June 2024

food safety. CCP derived from failure mode and effects analysis (FMEA) from NASA via the munitions industry to test weapon and engineering system reliability...

27 KB (3,194 words) - 21:01, 29 May 2025

DFMEA (Design Failure Mode and Effects Analysis) 14 PFMEA (Process Failure Mode and Effects Analysis) 15 MSA Study (measurement system analysis) 16 SPC (Statistical...

15 KB (1,969 words) - 10:58, 11 June 2025

Product Quality Planning (APQP) Failure mode and effects analysis (FMEA) Dimensional tolerance stack-up analysis using product and manufacturing information...

1 KB (108 words) - 15:53, 30 August 2023

body of a university in Assis, Brazil FEMA (gene), an enzyme Failure mode and effects analysis (FMEA) Femur Fima (disambiguation) This disambiguation page...

807 bytes (137 words) - 04:48, 22 February 2025

Reliability engineering (redirect from Critical failure)

BIST) (testability analysis) Failure mode and effects analysis (FMEA) Reliability hazard analysis Reliability block-diagram analysis Dynamic reliability...

97 KB (13,276 words) - 00:07, 1 June 2025

Search. Failure mode and effects analysis (FMEA) is a safety analysis method first developed for systems engineering which examines potential failures in products...

21 KB (2,921 words) - 16:05, 24 March 2025

Weeden, Marcia M. (1952). Failure mode and effects analysis (FMEAs) for small business owners and non-engineers: determining and preventing what can go wrong...

3 KB (359 words) - 07:32, 30 March 2024

DMAIC (redirect from Define, Measure, Analyze, Improve and Control)

any avoidable risks associated with the "improvement" using failure mode and effects analysis (FMEA) Create a detailed implementation plan Deploy improvements...

8 KB (1,040 words) - 22:06, 29 April 2025

Eliyahu M. Goldratt Evaporating Cloud Event chain methodology Failure mode and effects analysis (FMEA) Focused improvement Future Reality Tree Game theory...

2 KB (167 words) - 10:06, 1 January 2025

Fail-safe (section Fail safe and fail secure)

before the failure. Since many types of failure are possible, failure mode and effects analysis is used to examine failure situations and recommend safety...

19 KB (2,404 words) - 15:50, 25 April 2025

Pareto principle (redirect from Pareto analysis)

combined with other analytical tools such as failure mode and effects analysis and fault tree analysis for example.[citation needed] This technique helps...

24 KB (2,802 words) - 23:16, 11 June 2025

Structured what-if technique (category Systems analysis)

the aim of being quicker than more intensive methods like failure mode and effects analysis (FMEA). It is used in various settings, including healthcare...

3 KB (261 words) - 12:22, 8 January 2024

SAPHIRE (section Advanced analysis)

simultaneously and is able to handle extremely large analyses. Historically, NASA relied on worst-case Failure mode and effects analysis for safety assessment...

7 KB (1,001 words) - 03:48, 23 June 2023

of emerging technologies End of civilization Eschatology Failure mode and effects analysis Forecasting Foresight Future Future energy development Global...

15 KB (1,189 words) - 23:36, 30 May 2025

Scenario analysis Business impact analysis Root cause analysis Failure mode and effects analysis (FMEA) Fault tree analysis Event tree analysis Cause and consequence...

3 KB (286 words) - 04:44, 16 July 2024

organization Quality computer-aided quality assurance (CAQ) Failure mode and effects analysis (FMEA) Statistical process control (SPC) Computer aided inspection...

3 KB (331 words) - 10:11, 31 December 2024

publishes, including: The measurement system analysis manual The failure mode and effects analysis (FMEA) and Control Plan manual The statistical process...

8 KB (868 words) - 14:37, 26 May 2024

Process safety (section Definition and scope)

(HAZOP) review, developed by ICI in the 1960s, failure mode and effects analysis (FMEA), checklists and what-if reviews. These were mostly qualitative...

26 KB (2,978 words) - 17:05, 25 May 2025